What climber hasn’t dreamt of indulging their passion at home? Especially during lockdown?! Whether it’s for their own training or to get the kids started, most people can find a good reason for building their own wall! But if you want to make your dreams come true, there’s going to be some DIY involved (and it doesn’t need to be a nightmare)… From the Güllich board under the stairs to the climbing wall in the loft or cellar, where there’s a will there’s a way to build a bouldering wall at home! Read on to find out how!

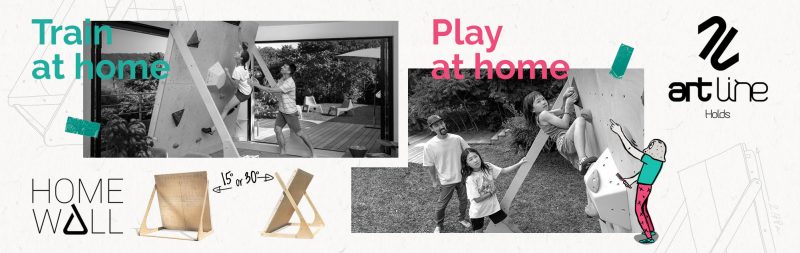

And for those who are definitely not handymen, ArtLine has the solution with the HomeWall, a free-standing wall with an adjustable angle to set at home. No need to be a DIY expert either, it’s as easy to put together as Swedish flatpack furniture:

Is my home suitable?

Whatever the size of what you’re planning to build, you’ll need to find a support structure that’s sufficiently solid. In fact this is what will determine whether your project is going to be somewhat modest, or pretty ambitious. You won’t be able to attach the structure to hollow supports such as brick or plasterboard without damaging the wall. You’ll need to go for more solid materials such as concrete, breezeblocks, stone or wood.

What about the format?

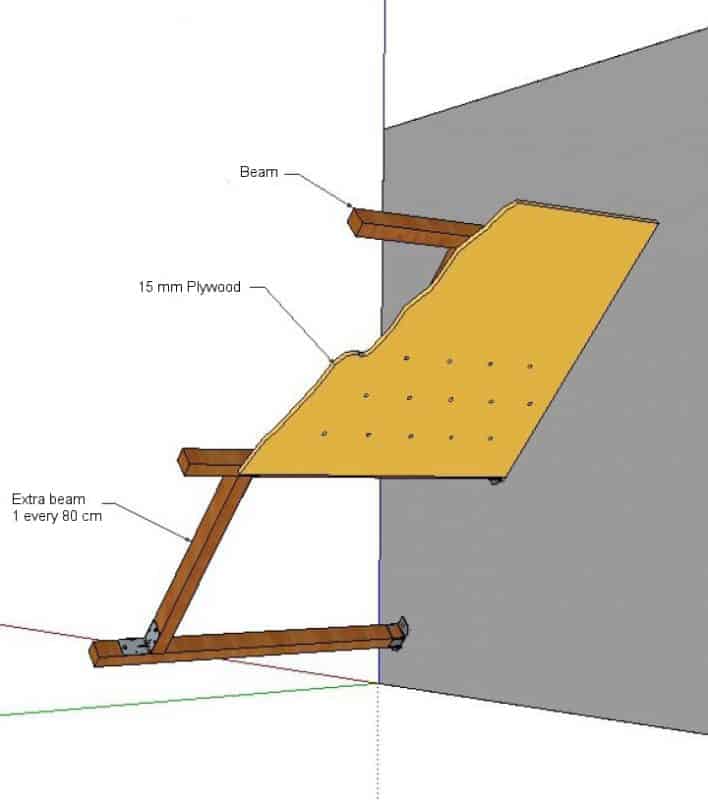

The available surface area, what you intend to use it for (strength, stamina, endurance), your level, the kind of holds you have or plan to buy… all of these things will dictate the profile of your wall. If you don’t have an expert carpenter on hand to build a complex structure, flat surfaces can be made more interesting by adding volumes, making your wall modular.

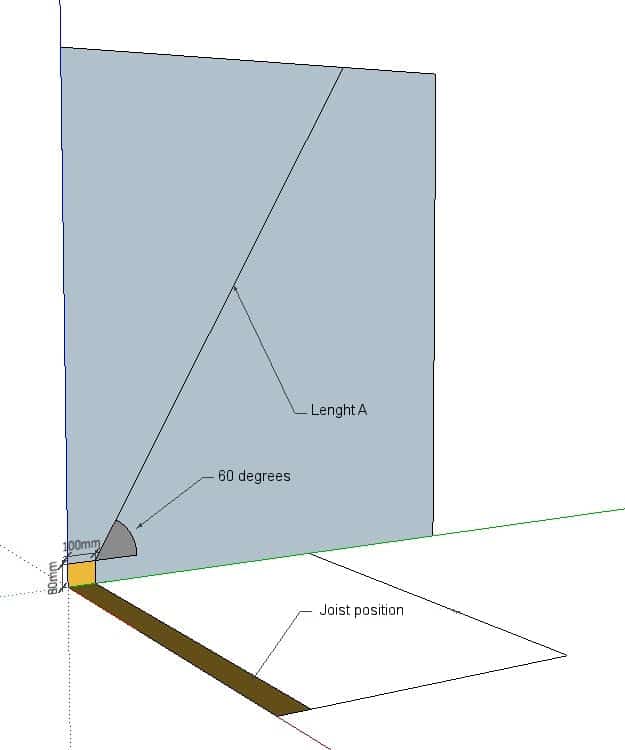

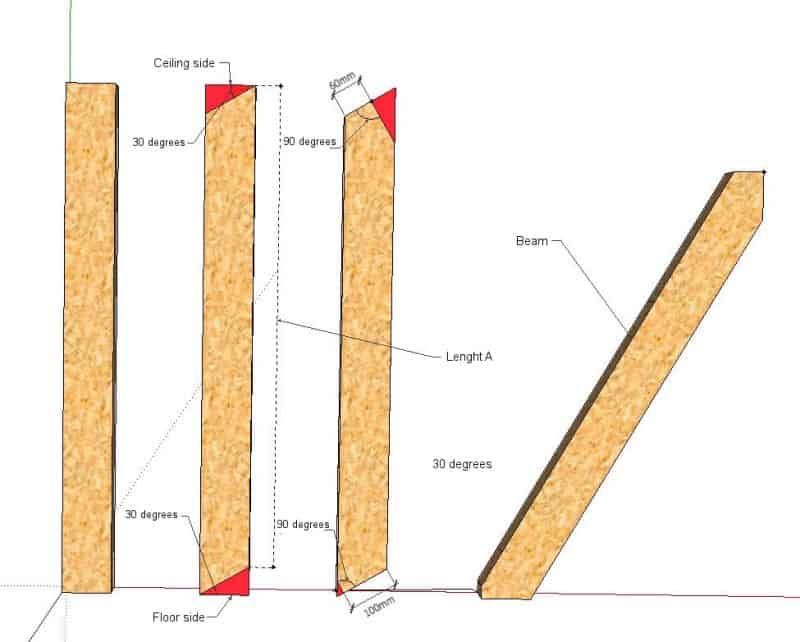

The classics are a 45° incline (takes up a lot of space), a 15/20° incline, vertical panels, and slabs with a 5-7° positive incline.

3D design tools like Google Sketchup can help you get an idea of the space you’ll need. A cardboard model works pretty well too!

What do I need ?

Tools:

- Power drill/driver

- 12 mm diameter wood drill bit

- Saw

- Hammer

- Measuring tape

- Spirit level

Wall structure:

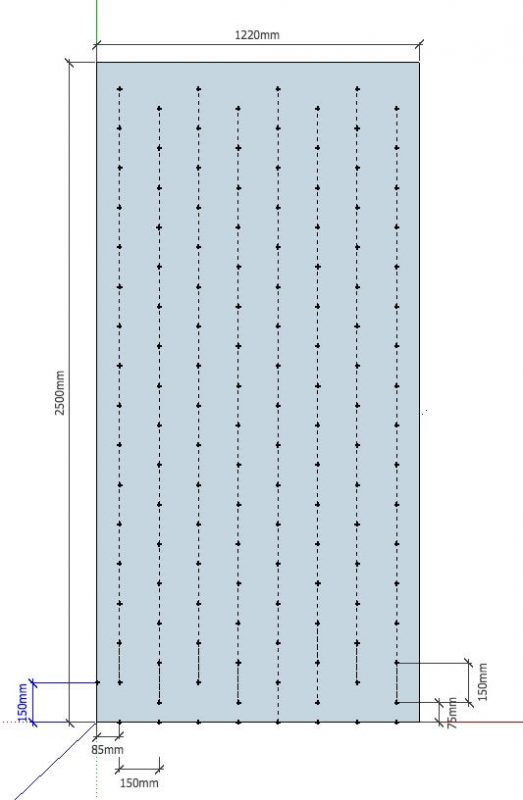

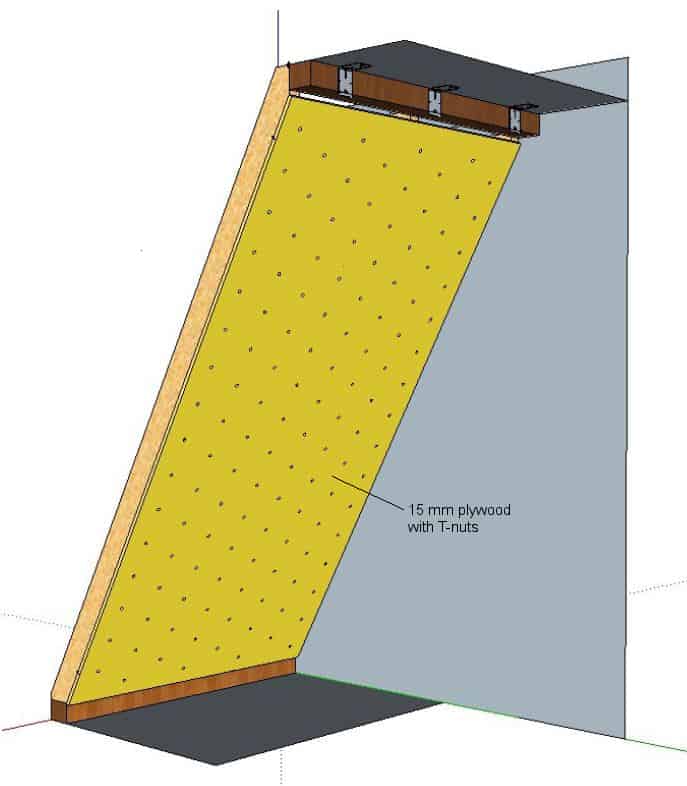

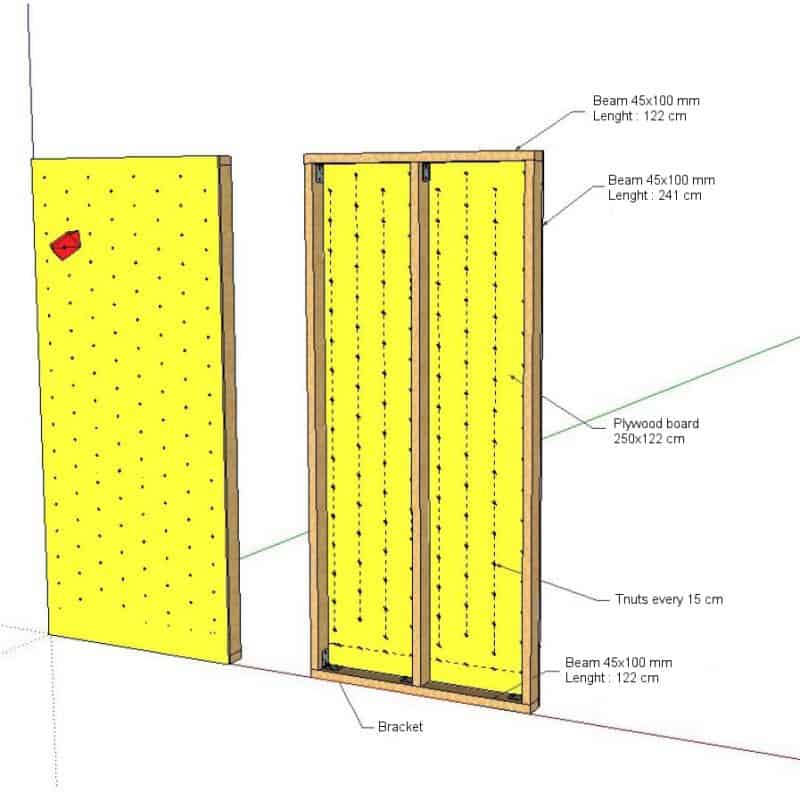

Panels: the most frequently used material is 15 or 18mm plywood, 12mm being too thin for the T-nuts. It comes in 122 x 210 cm or 150 x 310 cm boards. Some stores will cut those for you; it’s more expensive, but it can be handy if you don’t have the tools.

Particle boards such as chipboard or OSB are not suitable given the constraints of a climbing wall (T-nut screws get shredded, screw-on holds get pulled out) and keeping them rigid would require a lot of braces, which isn’t very cost-effective. Painting the panels makes it easier to wash them and get rid of dust and chalk. Often there won’t be a window, so painting them can help brighten the place up a bit.

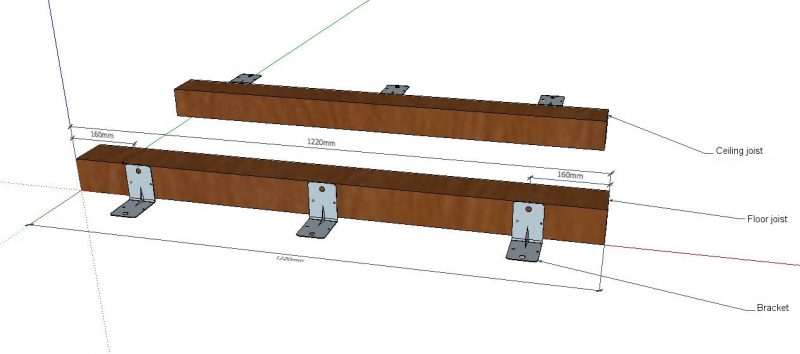

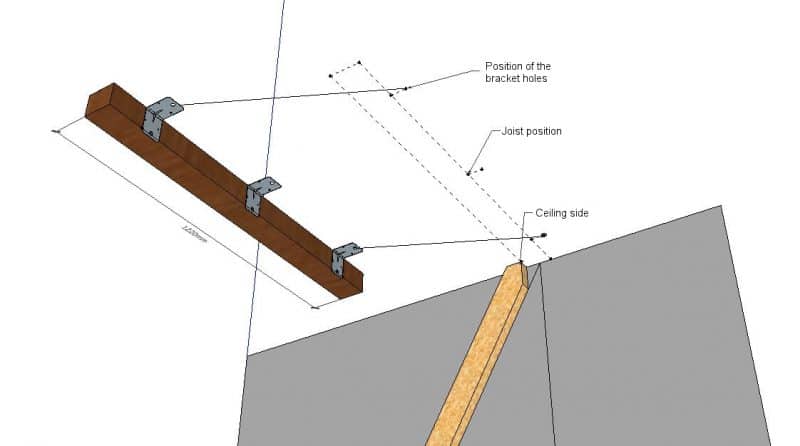

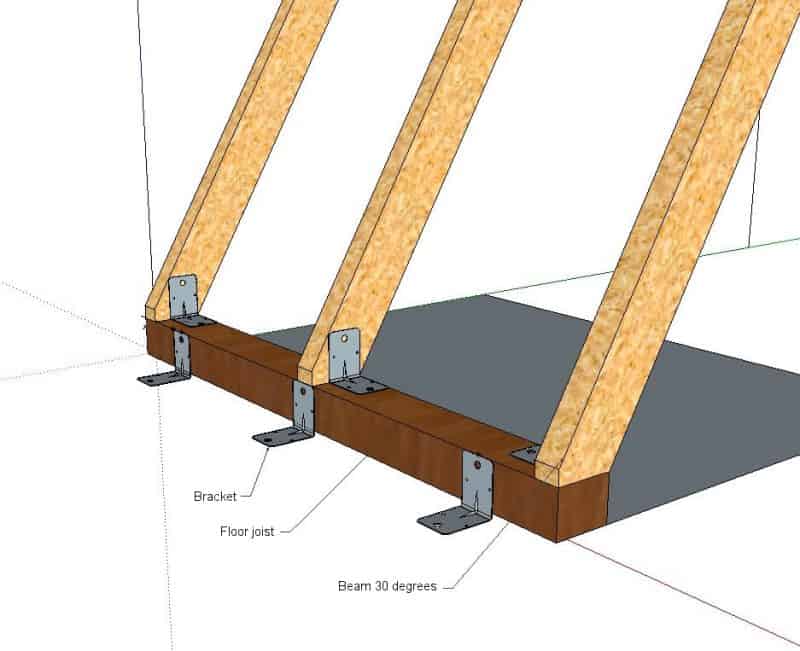

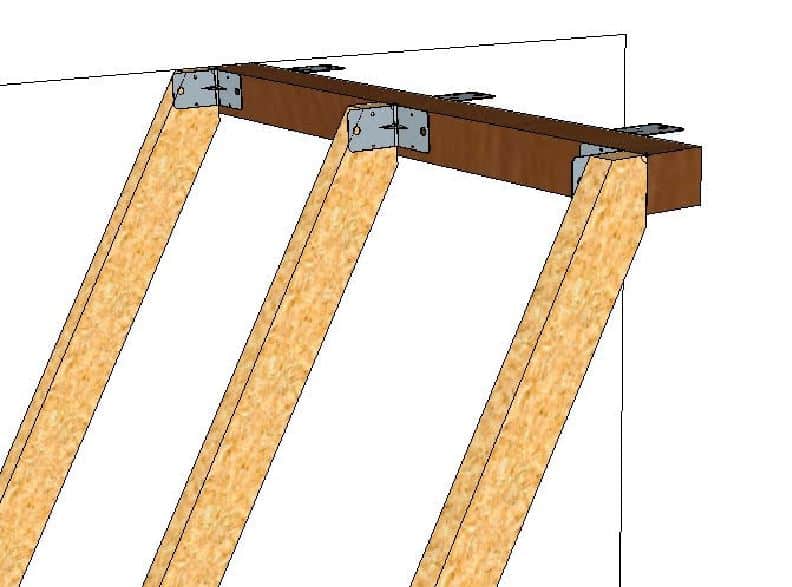

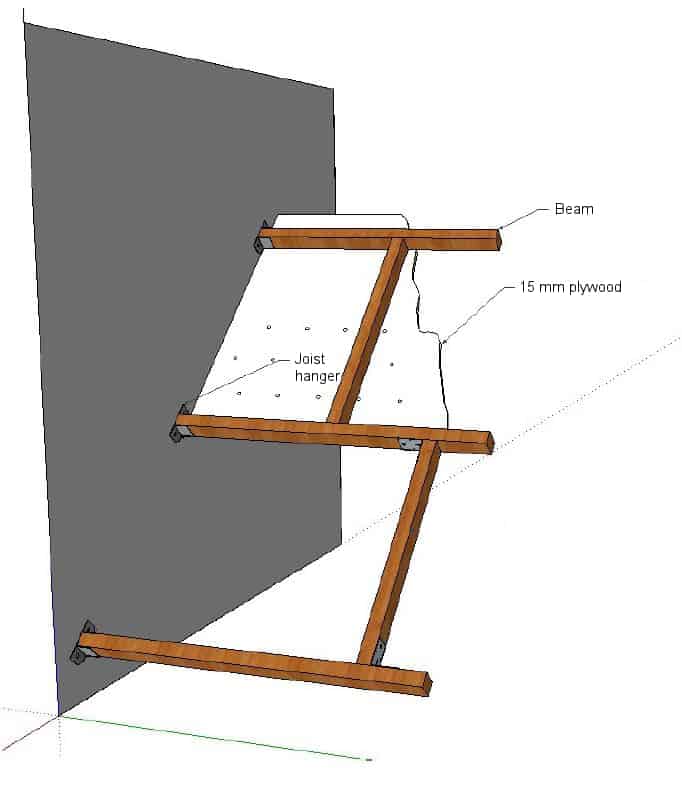

Frame: beams will form the frame: two horizontal joists (floor and ceiling) and several brace beams. The joists (80 x 100 mm) are made of plain wood and can be found in specialist stores. The planed brace beams (45 x 100 mm) are available in DIY stores. To attach the beams to each other, you will need connectors (joist hangers, reinforced angle 1, connecting plates). These come in sizes to fit the most frequently used pieces of wood. Different accessories (dowels, expansion bolts, cement, resin…) can be used to fix the frame to the supporting structure depending on what it is made of.

T-nuts: these nuts are inserted from behind the panel and the holds will be screwed into them, using CHC 10 mm screws. There are two types of T-nut. Screw-on T-nuts hold up well to power drivers, because of the two small retaining screws. Pronged T-nuts are easier and quicker to install and they are less expensive. However they can pop out if they are used intensively or regularly.